WALL-MAN®

An ATEX rated pneumatic personnel lift designed for paint spray booths and preparation booths where explosive gases and fumes are present...

For work on high-sided or very long vehicles, trailers, trains, wind turbine blades — at any height or position — scaffolds and ladders are still the most common access systems.

Purpose-designed WALL-MAN provides increased safety for operators while significantly improving efficiency and surface-treatment quality.

Controls in the operator’s cage move WALL-MAN along all three axes, including extending in, out, and around the workpiece in a spray booth. This versatility enables the operator to paint, mask, add signs, apply decals, or make repairs on high-sided vehicles with greater speed and safety than normally attainable using stepladders or scaffolding.

The compact design of WALL-MAN reduces congestion in spray booths and other confined work areas, and eliminates workplace obstructions caused by the use of conventional access equipment.

WALL-MAN is completely wall mounted. The platform’s lower support wheels run along the wall; there is no contact with the floor. WALL-MAN can be installed in new or existing booths, provided the structure can carry the modest loads involved.

Because WALL-MAN is powered only by compressed air, it is safe to use in hazardous environments such as spray booths. The user-friendly platform provides a highly efficient way to work. WALL-MAN significantly increases job safety and productivity - at low maintenance and operating costs.

Safety

- Fail safe operating mode both from within the cage and externally

- Fully enclosed operator cage providing a stable working platform with adequate working space for operator wearing breathing apparatus

- Pneumatic operation in all 3 axes of movement – no ignition risk

- International approvals and certification

- Many independent safety features throughout the design

Efficiency

- Move in all 3 axes of operation controlled by the operator at any height

- Logical and ergonomic operator controls

- In-cage air supply points for tools and spray guns

- Easy to use giving improved operator satisfaction and higher productivity

Reliability

- Easily maintained because the design comprises easily replaced standard components

- Over 20 years of continuous product development to consistently meet safety legislation

- Many hundreds of units supplied to date

WALL-MAN® Models;

WALL-MAN®

- Approx working height of up to 6.1m

- No contact with the floor

- Made to order

- Non slip floor in cage

- Three dimensional movement

- ATEX approved

Design: Mounted on the wall – no contact with floor, ergonomic operation

Construction: Welded steel

Finish: RAL 5015

Net weight: 320 kg

Energy: Entirely pneumatically operated

Functions: Three dimensional movement; up/down, in/out, left/right

Characteristics: Easy to install, minimum of maintenance.

Models: From 500 to 1300 mm telescopic extension –

lifting height (floor of cage) up to 4,5 m

Payload: 150 kg (one person + equipment)

Controls: Inside cage: Up/down, in/out, left/right

At ground level: Up/down

Brakes: Brake system in rail for steady positioning.

Optional: brakes on lower support wheels.

Air supply: Min. 6 bar, min. 350 ltr/minute supplied via hoses on self-retracting

reels or via energy chain. A compressed air outlet for air tools is provided in the cage.

Imposed loads:

Upper rail: Vertical load approx. 420 kg

Horizontal load approx. 120 kg

Lower support wheels: Vertical load 0 kg

Horizontal load approx. 120 kg

(Model 1000 – std. lifting height)

Approvals: CE, UL and ATEX certified.

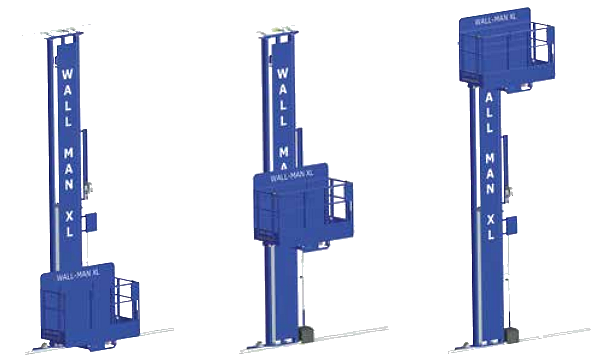

WALL-MAN® XL

- Maximum working height of 7.6m

- 250kg lifting capacity / payload

- 2m cage width

- Three dimensional movement

- Non slip floor in cage

- Made to order

- ATEX approved

Design: Mounted on the wall – ergonomic operation

Construction: Welded steel

Finish: RAL 5015

Net weight: 790 kg

Energy: Entirely pneumatically operated

Functions: Three dimensional movement; up/down, in/out, left/right

Characteristics: Easy to install, minimum of maintenance.

Models: From 1000 to 1300 mm telescopic extension –

lifting height (floor of cage) up to 6 m

Payload: 250 kg (two persons + equipment)

Controls: Inside cage: Up/down, in/out, left/right

At ground level: Up/down

Brakes: Brake system in rail for steady positioning.

Air supply: Min. 6 bar, min. 350 ltr/minute supplied via hoses on self-retracting

reels or via energy chain. A compressed air outlet for air tools is provided in the cage.

Imposed loads:

Upper rail: Vertical load approx. 0 kg

Horizontal load approx. 163 kg

Lower support wheels: Vertical load 1040 kg

Horizontal load approx. 163 kg

(Model XL 1000 – std. lifting height)

Approvals: CE, UL and ATEX certified.

Safety Features

Up/down:

- Safety flow restrictors in case of air loss

- Cage lowering duplicated at base

- Safety factor 11 on lifting chains

- Safety chain on air supply

- Chain slack protection

Sideways:

- Brake system for steady parking

- Upper Rail Guide rollers

- Rubber stoppers in rail

- Loss of air pressure allows manual movement

In/out:

- Pressurized cylinders for steady positioning

- Loss of air pressure allows manual movement

- Front bumper on cage

Miscellaneous:

- Non slip floor in cage

- Signal horn

- Chain protection panels

- Hook in cage for safety harness

- Self closing hinges

- Self closing latches

Find out More

Operator / Training Notes » Contact us about WALL-MAN® »WALL-MAN Summary

- Fully pneumatically powered

- Safe, secure 3-axis movement controlled by the operator

- Enables compliance with "Working at Height" regulations

- Improves safety, quality and productivity

- Operator satisfaction

- Widely used in preparation and finishing